born on 25 December 1746, in Wigan, England

died on 31 August 1835 at Birk Dault, Haverthwaite, England

died on 31 August 1835 at Birk Dault, Haverthwaite, England

Diese Seite auf

Deutsch

Deutsch

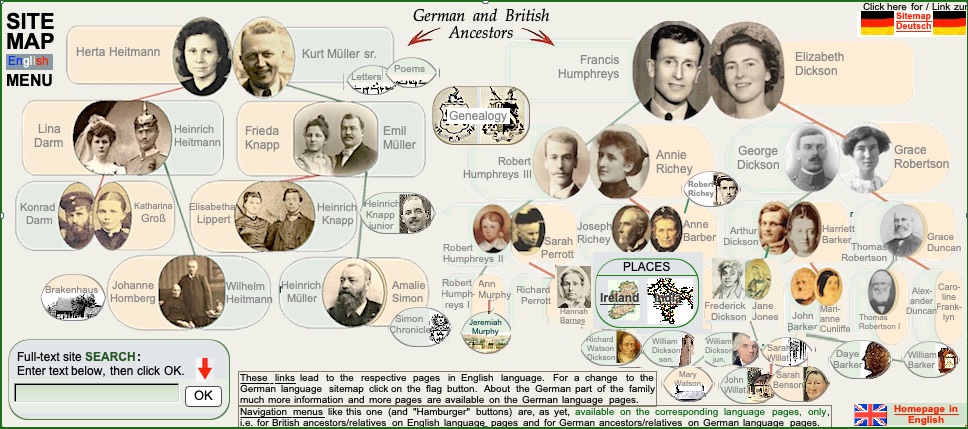

Family history Müller - Humphreys

© Kurt Müller 2017

Homepage auf

Deutsch

Deutsch

Homepage in

English

English

>> next >>

<< back <<

* We owe great gratitude to our cousin Michael Dickson who made this and other treasures accessible and consented to their publication here.

Daye Barker

"South Lakeland", the southern part of the Lake District, has had seven gunpowder mills. The oldest was established in 1746, the youngest and most modern,

"Black Beck"

at Bouth, was established in 1860 by the Dickson family (Daye Barker's granddaughter

Harriett

had married one of the Dickson brothers,

Arthur Dickson

).

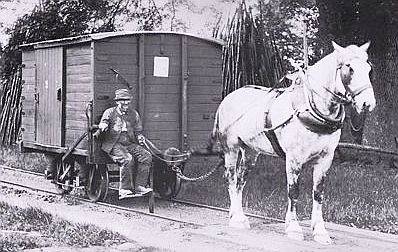

Alan and Glenys Crocker write: "The first sales of their gunpowder was 'Africa' powder and ships armaments. Until the 1850s when the Furness Railway opened the west coast railway line, all raw material and finished product was transported by sea. In those days the River Leven was navigable up to Low Wood, enabling product and raw materials to be transported on the river in 'flatties' - shallow draft, single masted vessels that were used extensively in Morecambe Bay.

Finished gunpowder was either stored at the service magazine in Roudsea wood (at the Frith at Greenodd), or in the works magazine at the eastern end of the site. However, the works magazine had to be relocated due to the opening of the Furness Railways branch line from Ulverston to Lakeside in 1868, as it was felt there was risk of sparks from the engines cause an explosion in the powder buildings only 200 yards away on the opposite side of the river. By 1808 Low Wood employed nine people and was becoming profitable even though raw materials were very expensive."

Daye Barker's father

William Barker

of Wigan, Lancashire was a gunsmith, at first, and later became famous as a clockmaker for his high quality astronomical clocks.

Iniitially Daye Barker set upon the same path; he became a successful clockmaker and joined his father's business. This mahogany longcase clock from about 1780 (right) is a result of the cooperation between father and son.

According to the historian

John Simkin

, in 1797 the factory co-owned by Daye Barker had 310 workers, among them 210 "parish apprentices", also called "workhouse children". See the extended description of the mill and its business by historian Ronald Mein: "

History of the Whitewater

", with a fine painting of the Mill in 1860.

born on 25th December 1746 in Wigan

died on 31st August 1835 at Birk Dault, Haverthwaite.

He married Elizabeth Sandys on 7th June 1788

in St Anthony's church

Cartmel Fell

(see right below);

the couple had 13 children, among them

John Barker

.

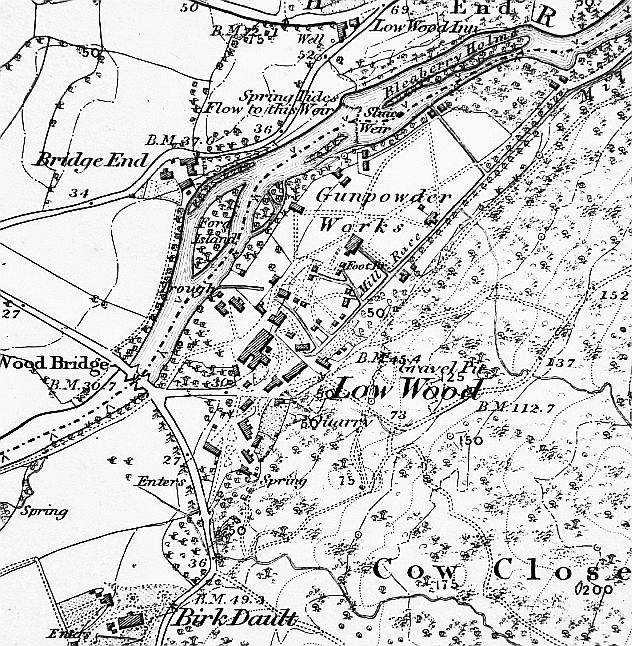

The Backbarrow Cotton Mill

About 10 years, though, after joining the cotton firm, in 1798, Daye Barker started a new business and founded the Lowwood gunpowder works (about six months before formally withdrawing from the cotton business, according to John Humphreys' sources). The site of it was only a few miles from the cotton factory down the River Leven and extended, when in operation, for 547 metres along the river. A license to make gunpowder at Lowwood was granted on the 22nd of October 1798. to a partnership including Daye Barker as the senior partner; Mr James King (an estate owner from Finsthwaite), Mr Christopher Wilson Jr. (a member of a Kendal banking family), and Captain James Foyer (a retired ship's captain, who had gained some fame when he captured a Dutch ship and amongst other roles acted as the company agent in Liverpool). The site was rented from the Bigland family of Bigland Hall. (Information from: News & Star, Carlisle, "Blast from the past gets visited"; 24 June 2011)

This radical step done by Daye Barker may have had to do with his father's death which had probably been expected because the father had suffered from a severe illness already in July 1786 or earlier. In the first weeks of 1787 (probably)

William Barker

died, and he was buried on the 8th of February 1787, but not in Wigan where he had been a very successful maker of high value products and an important and influential personality, but 70 miles north from Wigan in the Lake District, in Cartmel, the parish where his son's new life started. Probably William Barker died as a rich man and left a considerable patrimony to his children (we do not know if all three of them survived to that day). Being suddenly able to dispose of large sums of money may have triggered Daye Barker's decision for a fundamental change in every respect, but it may as well be possible that another decision was the spark to ignite all the other decisions in a chain reaction, the decision to marry a woman from the Lake District. The wedding, indeed, happened, one year later. He married Elizabeth Sandys, 23 years of age, with whom, between his 43rd and his 60th year of life, he had no less than 13 children. Near Haverthwaite he built a house for his family, Birk Dault, in 1798/1799 (as

Brenda Moss

says whose ancestor "Nathaniel Baythorpe worked there from 1800, and successive generations of his descendants also for over 100 years"; also mentioned by the

"Gunpowder Mills Study Group

" in their newsletter of July 1991, found by John Humphreys).

Also his professional and business life underwent a fundamental change. He invested large assets in the upcoming cotton business and became the co- owner of a large textile factory, the Backbarrow Cotton Mill (see below). There had been

a corn and later a paper mill

in this place for a very long time, and one of the two existing buildings ("south mill") burnt down in 1782 before it was rebuilt, then as a "cotton mill". There were 2 large mills, then (later 2 more), of 41 in the whole of Lancashire and 142 in Great Britain by 1787. "John Birch, Robert Robinson, and William Walmsley, Manchester fustian manufacturers, ran the Backbarrow Cotton Company from around 1781" (in the 1780s Birch also built a large private home,

Broughton Lodge

, which more than half a century latery later became the home of Daye Barker's son

John

and his family). "Daye Barker was their partner and manager until 1798, and after his departure the company continued to trade under the same name. Newspaper reports from 1808 relate to the bankruptcy of John Birch and Robert Robinson, cotton spinners and merchants, carrying on trade together as Backbarrow Cotton Twist Company" (Source: "Black Beck Hall, Ayside, Cumbria: Archaeological Building Recording",

Greenlane Archeology

2006).

"Before, until about 1790, the site had been used by the iron furnace built in 1711 by Isaac Wilkinson - the father of John Wilkinson, the famous iron master of Backbarrow and Iron Bridge - mainly producing cannons, gun carriages and cannon balls, so that a certain thematic continuity was sustained by the new purpose of making gunpowder." (from: News & Star)

John Wilkinson

contributed crucial components to James Watt's steam engine..

Alan and Glenys Crocker, co-founders of the "

Gunpowder and Explosives History Group

", write: "The reason for establishing the mills were to take advantage of the very profitable slave trade." News & Star add: "Initial sales were of gunpowder used in the slave trade, as well as powder for ships. Until the abolition of slave trade in Britain in 1807, the gunpowder formed part of the triangular slave trade route. Powder was exported to Africa to be exchanged for the slaves. They were taken to the Americas and sold. The ships returned to Britain laden with sugar, cotton and tobacco. Many barrel stencils showing export destinations, notably West Africa, were found on site and are now at the Abbot Hall Museum of Lakeland Life and Industry in Kendal. After 1807 Low Wood concentrated on the manufacture of blasting powder for use in the mining and quarrying industries." (from: News & Star, "Blast from the past gets visited"; 24 June 2011)

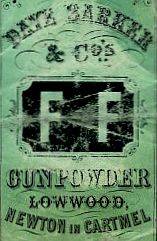

Left:

Daye Barker's gunpowder label

A year after starting the gunpowder business, in 1799, Daye Barker's participation in the cotton factory was formally ended. See below the notice of the "Dissolution of Partnership":

Low Wood tram with horse and worker

The clocktower of Low Wood

"Gunpowder manufacture was a dangerous business and Low Wood was regarded as a safe site.

"Black Beck"

was the most modern gunpowder works in the area but also the most dangerous (though, since Black Beck, in terms of the number of employees, seems to have been about 10 times as big as Low Wood, also a higher number of casualties should be expected there). Low Wood suffered a total of 6 explosions which caused 19 fatalities.

Low Wood powder mills closed in 1935. The most noticeable feature which survives of the Lowwood gunpowder works, on the left bonk of the River Leven, is the clock tower (right; now a

listed building

and converted in

offices

:) with its single clock face looking north-west across the river towards Haverthwaite", built in 1849. The clock itself - which is older than the tower - shows high quality of workmanship, what supports the story that Daye Barker made it himself. (Quotations from the

5th Newsletter

, page 5, of the

Gunpowder Mills Study Group

, Guildford, February 1989)

Thanks to James Shaw, present inhabitant of

Broughton Lodge

, we know that

the clock is now ringing again

!

Left:

Low Wood hamlet

Daye Barker

in 1785

This silhouette (left*), showing Daye Barker's profile, was done in the year 1785 when he was on the brink of changing his life fundamentally. In 1786/7, at the age of 40, probably unmarried and participant of the family business, he left Wigan and his identity of a successful clockmaker so thoroughly behind that not only his new existence seems to have stayed unknown to the inhabitants of his former world but also his old identity hidden to his new environment where he became an entrepreneur, husband, and father of 13!

In those times the workforce of textile factories predominantly consisted of children and minors, so-called "pauper apprentices". On his former website "

Leven Valley History

", the historian Ronald Mein wrote: "The industry needed small dexterous people who could work in small confined spaces and handle the fast moving machinery and children were ideal. In those days parishes were responsible for the care of pauper children who were seen as a drain on their limited resources, the parishes were only too pleased to be rid of these orphaned, abandoned or runaway children. The Backbarrow cotton masters took only a few pauper children from the nearby towns of Ulverston and Dalton, the rest came from large cities like Manchester, Liverpool and London." To save some of Daye Barker's honour, it must be said, though, that Backbarrow became particularly notorious for such behaviour only long after his withdrawal from the firm.

The workers lived in a tiny hamlet of stone houses along the roadside with the river Leven running nearby (see: "

The Cumbria Directory

" ).

"Black powder was prepared by mixing the three ingredients of saltpetre, charcoal and sulphur in the damp state for several hours. This was done formerly in barrels by lignum vitae balls, but at Lowwood in the incorporating mill under fine grain crenoidal limestone edge runners. The object was to coat every charcoal and sulphur particle with a layer of saltpetre. Originally the gearing was above the edge runners, but this caused explosions by bolts etc dropping into the mix. Later the gearing was placed underneath.

The resulting cake was then pressed between layers of copper or ebonite plates in the press house to form press cake. This was then granulated in the corning mill. Here the three substantial walls remain, 25 feet high. A belt elevator took broken pressed cake to seives for granulation or later to a series of toothed metal rollers, before being packed in barrels. Holes can be seen in the walls through which the roller drive shafts passed. This was the most dangerous stage, so the roof and front of the building, as with the incorporating mill, were lightly constructed to blow out in case of explosion. Accidents were frequent. The finished powder was sometimes coated or polished with black lead to keep it dry." (from an article by John Garbutt in The Newsletter of the

Cumbria Industrial History Society

, December 1994)

For more information about the production of gunpowder in those days see the page of

"Black Beck"

.

Daye Barker died in 1835. He was succeeded by his sons, Daye Barker, who lived at Birk Dault

and had no offspring, and

John Barker

, who lived at Broughton Lodge.

Menu